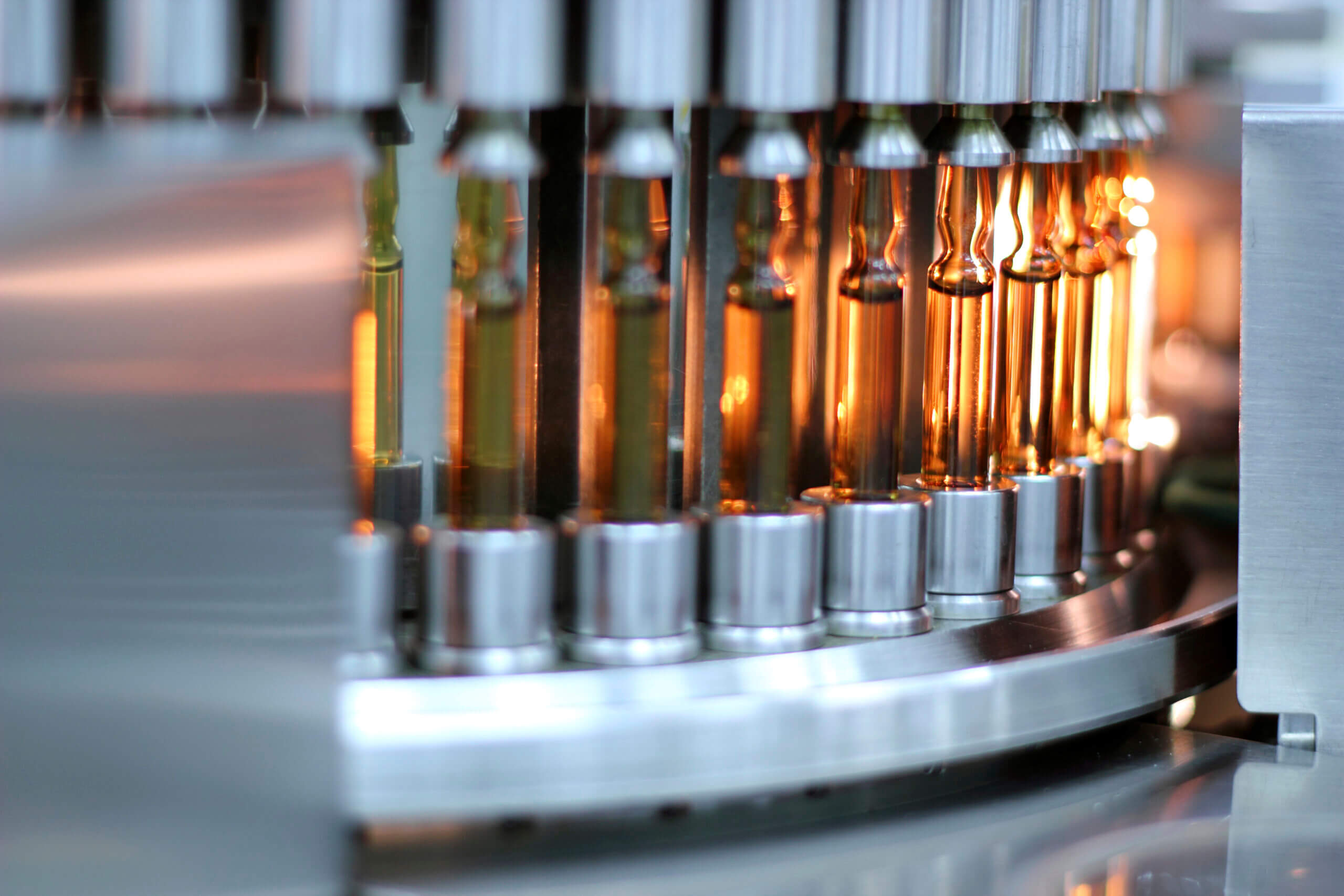

Cell Growth Vaccine Monitoring and Control System

An FDA-regulated automation system to support the manufacturing of the Varicella (chickenpox) vaccine

One of the world’s largest pharmaceutical companies partnered with PSI to design and develop an FDA-regulated automation system to support the manufacturing of the Varicella (chickenpox) vaccine. The project required integrating advanced robotics into a tightly controlled pharmaceutical environment, enabling seamless communication between mobile robotic carts and a centralized digital control system (DCS) across multiple manufacturing rooms.

PSI led the full system design and software development effort, creating a robust software platform that translates communications between the robotic carts—each used to transport materials during vaccine production—and the DCS. The system supports up to ten communication ports with as many as 32 carts per port, tracking their status and locations in real time while managing bidirectional command and status updates. Notably, the platform supports two distinct cart types that communicate using entirely different protocols over the same communication port, requiring careful protocol handling and integration.

To support validation and ensure system reliability under all operating conditions, PSI developed a comprehensive suite of simulators and stress-testing tools, including simulated carts and DCS interfaces with scripted test sequences. These tools helped expose edge-case issues, ensure compliance, and produce detailed audit trails. Core components of the system include a mirror-image port communication translator (supporting both transmission and reception), OPC interface integration, operating system services, configuration management DLLs, audit trail logging, and other critical modules.

The software was developed using Visual Basic and Visual C++, leveraging MFC, STL, and OPC for deployment on Windows NT and XP platforms. PSI also delivered complete documentation aligned with FDA Title 21 CFR Part 11 and Part 820 compliance requirements, including project plans, software requirements, design documents, test plans, factory acceptance tests, and user guides.

The resulting system has operated successfully for over two decades and continues to be deployed at global pharmaceutical manufacturing sites. PSI’s solution not only met strict regulatory standards but also delivered long-term reliability and scalability in support of high-volume vaccine production.

Quick Facts

PSI’s Role: software design, software development, text execution, post-release maintenance

- Platforms: Visual Basic and Visual C++, leveraging MFC, STL, and OPC for deployment

- Windows OS: NT and XP